Today, more than ever, companies are faced with rising waste disposal costs and legislation aimed at reducing waste, while encouraging recycling. Furthermore, companies are being challenged by governments and consumers, to demonstrate lower CO2 emissions and circular economy initiatives.

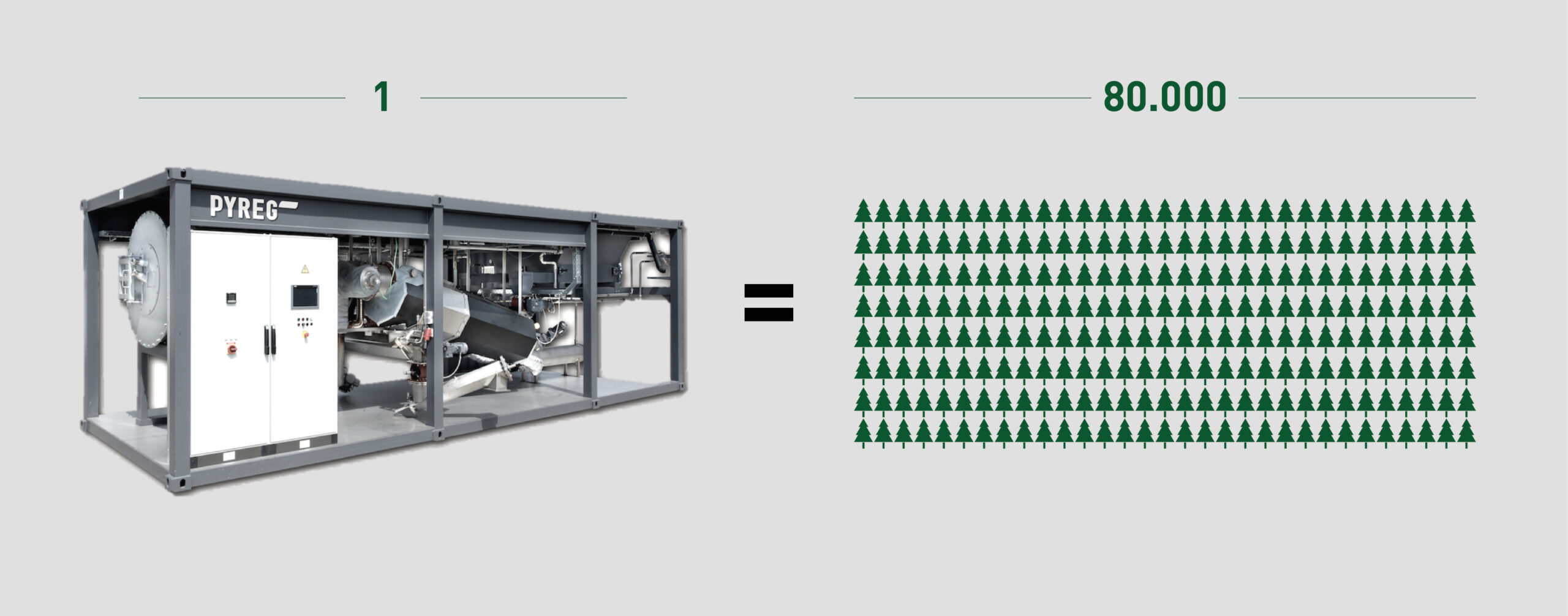

Innovative solutions to meet these challenging requirements: PYREG systems can transform your waste into value-added products, while providing a proven solution to help lower your Carbon Footprint. The same, proven PYREG technology that was first used to carbonize sewage sludge into high-quality phosphorus fertilizer, can just as well be applied to transform mixed waste into a product called biochar. Biochar sequesters CO2. Used as a soil improver it reintroduces important elements in the environment, substitutes highly polluting materials of different use, and gives all of us the opportunity to create a stronger circular economy.

The disposal of industrial and consumer waste is becoming increasingly complex and cost-intensive worldwide. The legal directives required by environmental policy aim to reduce waste, eliminate landfills and increase raw material reuse. With a PYREG system, you can reduce your waste volumes by more than 90% and transform that waste, through our unique carbonization process.

Solutions to your waste disposal challenges, helping your company to achieve its sustainability goals. Our systems can be used in applications ranging from waste volume reduction, to sanitization of waste, to the recycling of mixed food & packaging waste.

Separation of mixed waste often entails long transport distances, high sortation costs and low residual value of recovered materials (due to contamination). However, PYREG systems offer a proven alternative to those cost-prohibitive, mixed waste separation models. By applying PYREG technology, your company can actually upcycle its waste into valuable biochar, thereby “closing the loop” and demonstrating a true Circular Economy. With a compact modular design, PYREG plants can be placed virtually anywhere, in an area roughly the size of a 3-car garage.

The PYREG system ensures that all input waste material is sanitized in the course of carbonisation process. During this carbonisation process, the majority of the carbon is actually sequestered in the resulting biochar, thereby inhibiting the release of CO2 into the atmosphere, for centuries. Furthermore, as the PYREG system operates at temperatures of up to 750°C, organic-based pollutants (such as solvents and microplastics) are practically eliminated and mineral pollutants are filtered, to ensure they cannot re-enter the environment. The process itself is autothermal; meaning that only energy, generated by the carbonization of the waste material, is used to perpetuate the operation of the PYREG system.

0 Kommentare