premium carbonization technology for a valuable business proposition

As biochar pioneer, we have been setting standards in decarbonization and sustainability with our patented technology for over a decadeThe latest generation:

The Pyreg PX

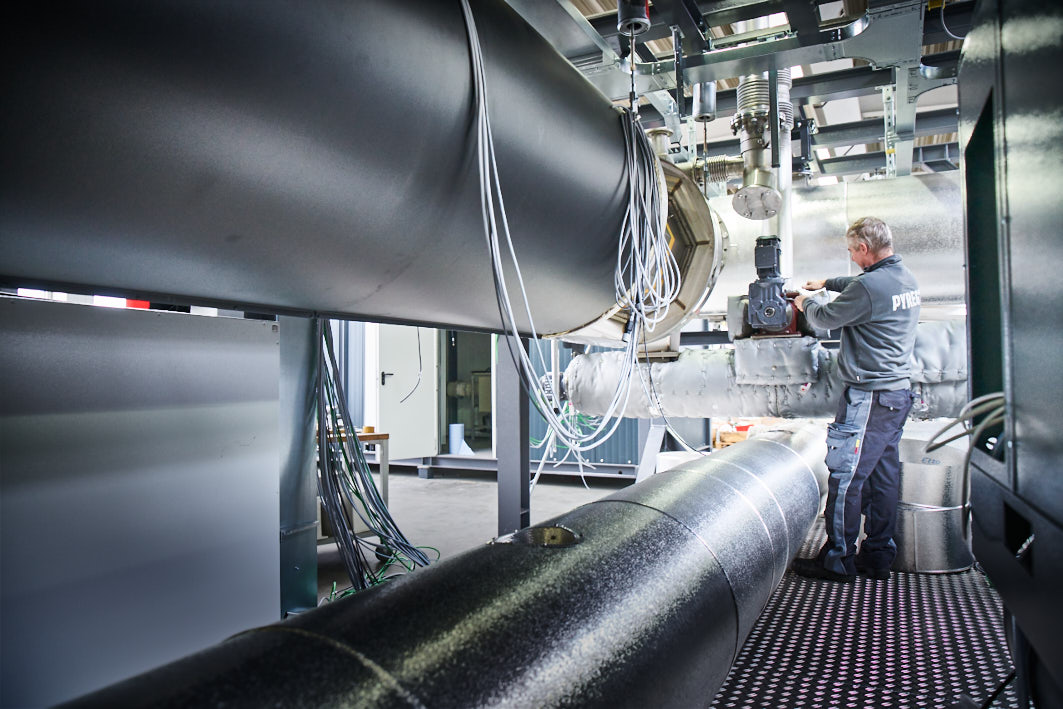

Our plants are individually customized to your needs. No matter whether 500 or 1,500 kW fuel capacity. Each system contains compact, decentralized carbonization technology that can be easily integrated into an existing infrastructure and your material cycles. The biomass or sludge is not incinerated, but rather gently degassed and then carbonized at temperatures between 500 and 750 °C – in an oxygen-limited process. The clean, renewable thermal energy from a PYREG system, provides up to 4.8 million kWh per year.

100 % efficient, sustainable & profitable

external energy demand

<3%

waste reduction

90%

hygienization

>99%

elimination of fine dust

>99%

renewable energy

100%

Carbon Deoxide Removal Technology

advantages of our technology

multi-material capability

continous and safe process

- State-of-the-art automation and control technology

- Futureproof data acquisition and processing

- > 99 % elimination of fine dust in exhaust gas due to special process gas filter

- Meets EU emission limits

CONTROL OF CARBONIZATION

At the same time, organic-based pollutants (such as solvents and microplastics) are virtually eliminated and mineral-based pollutants are filtered out at temperatures of up to 1000°C in the combustion chamber. Efficient, climate-friendly and without harmful by-products.

variability in heat delivery systems

- Maximum variability in heat extraction: Hot water, steam, thermal oil

- up to 4.8 GWhth usable renewable heat energy per year

Comparing the different models

PYREG systems set international standards for quality and technology and are recognized by the US Environmental Protection Agency (EPA). The benefits for both systems are identical (PX 500 & PX 1500). They only vary in performance and specifications.

| Fuel capacity | 500 kW |

| Annual throughput | 1.100 t OS |

| Annual production | 300 t OS |

| Carbon removal potential | 700 t CO₂ /a |

| Maximum heat output | 200 kWth |

| Electricity consumption | up to 12 kWel |

| Size | 12 x 6 x 5 m (l, w, h) |

OS = Original substance. Maximum figures based on 8,000 operating hours. Wood with 48% carbon content & 6% ash.

| Fuel capacity | 1.500 kW |

| Annual throughput | 3.300 t OS |

| Annual production | 900 t OS |

| Carbon removal potential | 2,100 t CO₂ /a |

| Maximum heat output | 600 kWth |

| Electricity consumption | up to 40 kWel |

| Size | 13 x 7 x 7,8 m (l, w, h) |

OS = Original substance. Maximum figures based on 8,000 operating hours. Wood with 48% carbon content & 6% ash.

| Fuel capacity | 6.000 kW |

| Annual throughput | 13.000 t OS |

| Annual production | 3.600 t OS |

| Carbon removal potential | 8.400 t CO₂ /a |

| Maximum heat output | 2.500 kWth |

| Electricity consumption | up to 120 kWel |

| Size | 21 x 14 x 7.5 m (l, w, h) |

OS = Original substance. Maximum figures based on 8,000 operating hours. Wood with 48% carbon content & 6% ash.

| Fuel capacity | 500 kW (sludge) |

| Annual throughput | 1.100 t OS |

| Annual production | 670 t OS |

| Carbon removal potential | 320 t CO₂ /a |

| Maximum heat output | 200 kWth |

| Electricity consumption | up to 16 kWel |

| Size | 12 x 6 x 5 m (l, w, h) |

OS = Original substance. Maximum figures based on 7,000 operating hours. Wood with 48% carbon content & 6% ash.

| Fuel capacity | 1.500 kW (sludge) |

| Annual throughput | 3.100 t OS |

| Annual production | 1.900 t OS |

| Carbon removal potential | 1.000 t CO₂ /a |

| Maximum heat output | 575 kWth |

| Electricity consumption | up to 48 kWel |

| Size | 13 x 7 x 7,8 m (l, w, h) |

OS = Original substance. Maximum figures based on 7,000 operating hours. Wood with 48% carbon content & 6% ash.

Scalable technology

CO₂-reduction that pays off

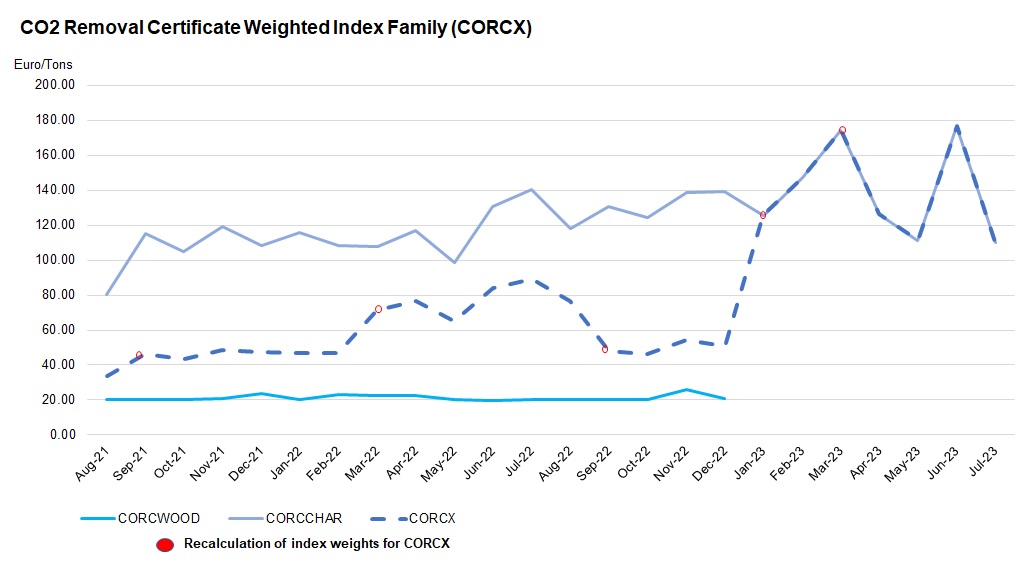

PYREG customers have the opportunity to monetize the carbon removal activity of their biochar production on various marketplaces. This is because biochar is a recognized carbon removal technology that is urgently needed to meet our global climate goals. For example, the Puro.earth platform helps corporate buyers create a long-term sourcing portfolio to neutralize their CO₂ footprint and achieve NetZero with CO₂ removal certificates (CORCs).

Disclaimer:

Nasdaq Copenhagen AS or any of its affiliates (“Nasdaq”) assumes no liability for loss or damages related to or arising out of the use of the CORC Removal Reference Price Index family (the “CORC Index”). Nasdaq expressly disclaim all warranties of accuracy, completeness, merchantability or fitness for a particular purpose with respect to the CORC Index. Neither Nasdaq nor any third party make any express or implied warranties or representations regarding the results which may be obtained as a consequence of the use of CORC Indexes or regarding the value of CORC Indexes at any given time. Nasdaq shall in no case be liable for errors or defects in CORC Indexes, nor obliged to provide notice of or otherwise publish errors in CORC Indexes

CORC Indexes is provided by Nasdaq Copenhagen AS and shall not without Nasdaq Copenhagen AS´s prior written consent be used:

- As reference for the issuance of a financial instrument;

- As reference for the determination of the amount payable under a financial instrument or a financial contract;

- As reference by a party to a financial contract;

- For measuring the performance of an investment fund, of defining the asset allocation of a portfolio, or of computing the performance fees;

- For any other purpose which may qualify Nasdaq Copenhagen CORC as a benchmark in accordance with regulation (EU) 2016/1011 of the European Parliament and of the European Council on indices used as benchmarks in financial instruments and financial contracts.

Worldwide service from the market leader

-

Analysis of your residues and test carbonization in the PYREG laboratory

-

Support with permit applications

-

Consulting and support regarding necessary infrastructure, technical interfaces for installation, commissioning and plant operation

-

Supervision of installation and assembly of all components

-

Technical training and certification

-

Fast on-site service

-

state-of-the-art remote diagnostics and remote monitoring

Our unique process is autothermal

The energy generated by the carbonization of the waste is used for continuous system operation.

Marcel Rensmann

Head of Technical Sales

Interested?

Would you like to learn more about our solutions for CO₂ reduction, CO₂ certificates, and recycling?

Get in touch with us.