GOING CIRCULAR

Circular Economy is the future. You can join it today.

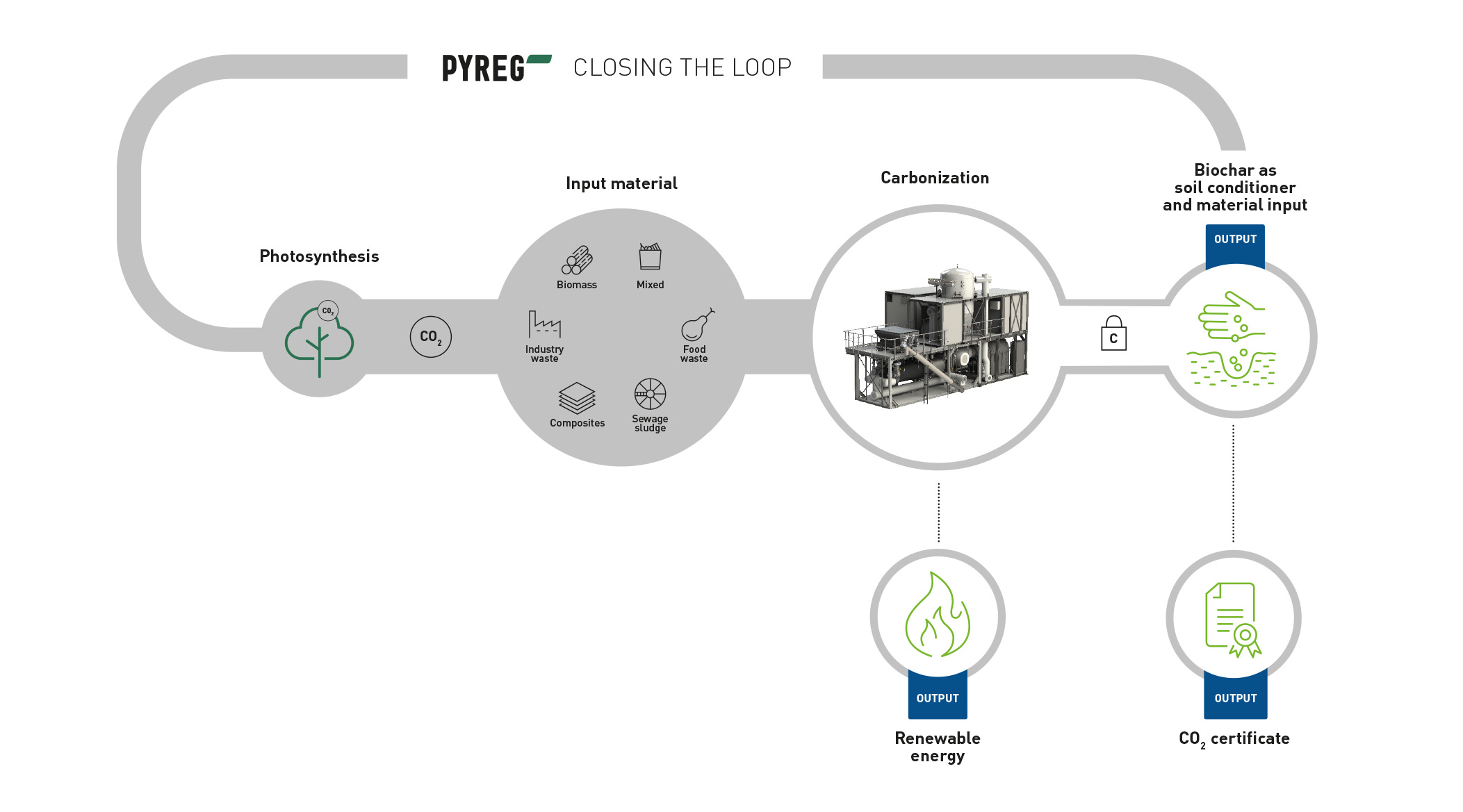

Carbonization drives sustainability

and enables circularity

With our modularly manufactured plants, industrial companies, agricultural and sewage treatment companies can convert their carbon-containing “waste” on site into premium Biochar and at the same time generate renewable energy. In this way, a residual or problematic material is turned into high-quality, climate-protecting Biochar.

Biochar enables permanent storage of the CO2 bound in the residual materials. Operators of PYREG plants thus not only close material cycles, but also create nature-based carbon sinks.

A smart solution for the end-of-life challenges of your products: Closing the loop with added value and climate protection in one!

Make sustainability

your new business model!

The going circular advantages can be used, either as a yield model or, to benefit the companies CSR goals.

CO2 Sink

Certificates

Waste Volume

Reduction

Extracted Re-

newable Energy

High Quality

End-Product: Biochar

CO2-Sink Certificates

CO2-Sink Certificates

2,100 t CO2/year*

262,500 €

(Puro Earth, 01.11.22, base price 125€)

Upcycling your waste

Upcycling your wasteto biochar

900 t/year

= 720,000 €

CO2-Carbon Storage

CO2-Carbon Storage

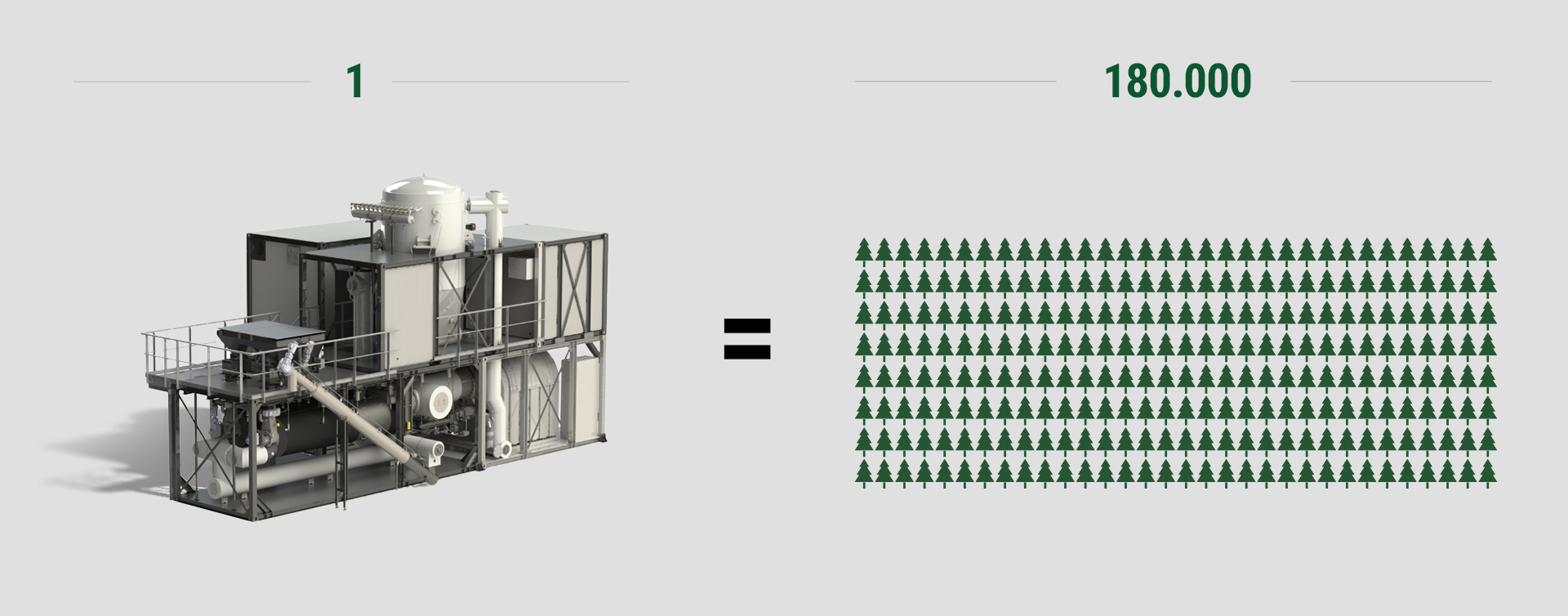

2,100 t CO2/year

180,000 Trees

Renewable Energy

Renewable Energy

600 kW ≙ ~ 4,8 GWh/year

240,000 € /year

+ additional savings

compared to liquid gas 1,300 t CO2

By example woodchips 80%DS, 19 MJ/kg DS

* Production-related CO2 emissions have already been deducted

With Pyreg, you meet the United Nations SDGs

(Sustainable Development Goals)

The sustainability goals set by the UN are not only relevant for companies that report according to international standards. They define a shared responsibility for all companies along their own supply chain and materiality.

PYREG technology closes the loop and sequesters CO2. Meet the requirements of the UN SDGs today instead of waiting for tomorrow!

Biochar increases soil properties and fertility and thus contributes to a sustainable agriculture.

Due to its enormous surface Biochar offers an excellent capacity to store nutrients and water in the soil.

PYREG carbonization generates renewable energy that can either be used on site or be fed into the local heating network.

PYREG closes the loop in carbon cycles by transforming organic waste into a valuable resource, clearing the path to "green transformation" for these industries.

Biochar can be extracted from the organic waste of cities and then serve as a water reservoir for urban green spaces that are burdened by climate change.

By recycling carbonaceous waste in a sustainable way, PYREG technology closes the loop, lowers the CO2 footprint and generates renewable energy at the same time.

Biochar is included in the IPCC special report as a promising negative emission technology (NET), mitigating climate change.

Due to its enormous surface of 200-500 m² per gram and a high porosity, Biochar retents water and nutrients dissolved in it and thus combats desertification and biodiversity loss.

Biochar – the key ingredient for

a sustainable economy

What makes Biochar special? High-quality biochar has a great variety of characteristics and effects; it acts like a sponge, retaining water and nutrients. These qualities enable biochar to be used in many applications, such as:

Feed

Additive

Soil

Additive

Filling material

in production

Building material

additive

The quality and therefore the applications areas depend on the input material. Low-quality biochar can be used as filling material in production or as a building material additive in asphalt or concrete.

Either way – waste can be used again in a sustainable way to close the loop, demonstrating a true Circular Economy.

Need Financing?

ENGINEERING SUSTAINABILITY

During this carbonization process, the majority of the carbon is actually sequestered in the resulting Biochar, thereby inhibiting the release of CO2 into the atmosphere, for centuries. This sequestered CO2 amount can be certified and used either to achieve sustainable corporate goals or to trade them on the open market. (Source: Waldzentrum Universität Münster (2019))

OPERATING 1 YEAR

EQUIVALENT TO THE YEARLY GROWTH OF 180.000 TREES